What is Borosilicate Glass, Why it’s Better?

Borosilicate glass 3.3 is a type of glass containing Boric Oxide that allows for a very low thermal expansion coefficient. This means that like normal glass, it won't break under sudden temperature changes. Its durability has made it the glass of choice for laboratories and pilot plants/kilo labs for scientific glassware.

For decades, borosilicate glass has been a preferred construction material for almost all modern laboratory glassware and glass process equipment, with broad use in the chemical and pharmaceutical industries. Its unique chemical and thermal resistance properties make it genuinely an outstanding glass with specific characteristics that differentiate it from other construction materials.

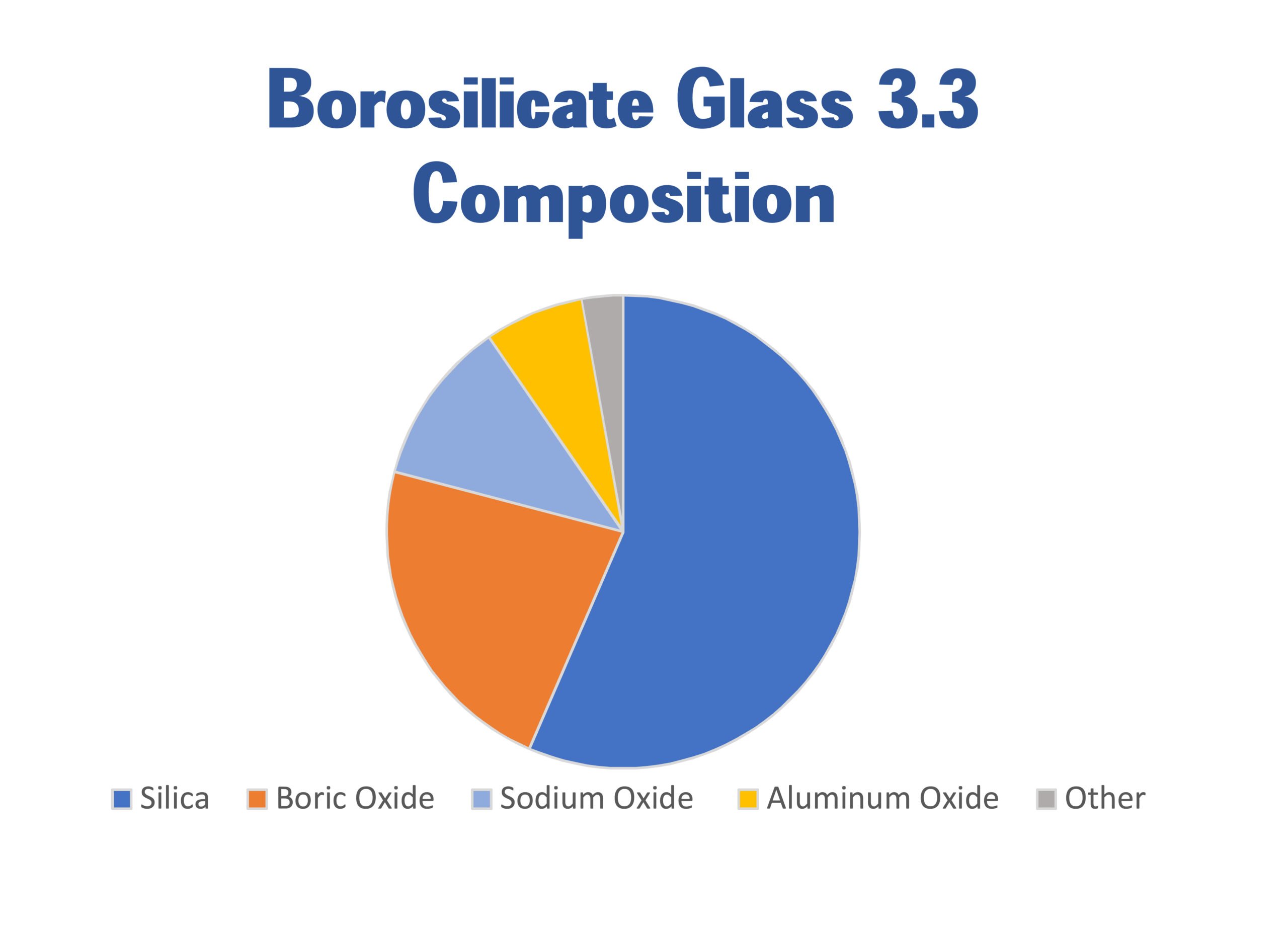

But let’s take a step back for a moment before we get ahead of ourselves and engage in a Borosilicate Glass speed level (or technical speaking Borosilicate Glass 3.3). What is borosilicate glass and what makes it different from other forms of glass? Popular glass is usually a silicate glass composed of sand, sodium-carbonate and limestone, such as float glass, and regular kitchen drinking glasses. Borosilicate glass is separated by the addition of boric oxide with silica.

The object of adding boric oxide is to produce a product with a higher melting point that is less dense. Borosilicate glass 3.3 is useful for a range of applications beyond process plants and pipelines, including cookware, microscope and telescope lenses, stage lights, guitar slides, and art construction, thanks to its high-temperature allowance and superior durability.

The few great advantages that will get you loving borosilicate glass when it comes to chemical laboratory equipment and process plant components are:

Optical Properties

Glass has a smooth surface that offers an excellent view of what is going on inside the equipment, enhancing the efficiency of inspection in each process, particularly compared to the range of plastics, metals and other building materials. Glass, in terms of clarity, is a good option.

An alternative shielding of the glass with the addition of the transect coating. There is a slight drop in visibility as added to the surface for its proper protection.

Corrosion Resistance

Similar to the properties of glass equipment, it has unmatched corrosion resistance to water, neutral and acidic liquids, concentrated acids and acid mixtures, and chlorine, bromine, iodine and organic compounds. Its chemical attack resistance, both overextended exposure times and at temperatures above 100 C, is superior to that of other metals and other materials. There are only a few chemicals that can induce visible corrosion of the glass surface – hydrofluoric acid, condensed phosphoric acid and heavy caustic solutions at elevated temperatures. However, borosilicate glass can withstand caustic solutions of up to 30 percent concentration without difficulties at ambient temperatures.

Temperature Range

The high-temperature tolerance of borosilicate glass makes it attractive in chemical and pharmaceutical processes. The maximum permissible operating temperature for borosilicate glass is 200°C (due to limiting factors such as PTFE gaskets) (due to limiting factors such as PTFE gaskets). The glass starts to soften above a temperature of 525 ° C and the liquid state changes above a temperature of 860 ° C. Conversely, it may be cooled down to the highest practicable negative temperature, but for use down to-80 ° C is usually preferred. Another value of the temperature allowance is the ability to expose borosilicate glass to two different temperatures at the same time (though for safety reasons it is recommended that temperature difference does not exceed 120 deg C).

Structural Integrity Due to Low-Temperature Expansion

The value of low thermal expansion is directly related to the broad temperature difference.

Since borosilicate glass does not stretch like ordinary glass, there is a better transition between temperatures and the ability to tolerate different temperatures at the same time. Borosilicate glass has an exceptionally low coefficient of linear expansion (3.3 x 10–6 K–1) owing to its low thermal expansion. In addition, the low thermal expansion coefficient reduces the need for costly steps to compensate for thermal expansion arising from temperature increases.

This is particularly important in the layout of long lines of glass pipelines, maintaining a high degree of structural integrity. For this reason, borosilicate glass is an accepted and tested material used in the production of pressure equipment.

Inert Behavior

Since there is no contact or ion exchange between the process media and the glass, there is no catalytic effect. The inertness of borosilicate glass therefore means that it is non-flammable and does not pose an environmental danger. Owing to the inert behaviour of glass, there are no odours or flavour modifications and can also be used nearly unrestrictedly in pharmaceutical applications and in the food and beverage industry. Borosilicate Glass parts and systems are available in a broad variety of sizes and configurations to create a personalized approach depending on the scale of the operation, from laboratory/research and development to complete manufacturing. These processes include but are not limited to) reactions, distillation, evaporation, extraction, absorption & cryogenic systems.;

Cleanliness

Some materials of construction can pose housekeeping issues when it comes to ease of cleaning. Not glass! The anti-stick, nonporous surface makes borosilicate glass a popular choice for pharmaceutical GMP compliant applications. And its transparency allows you to see when equipment needs to be cleaned without the need for interrupting the process and performing an internal inspection.

Compact Architecture

Compared to structures constructed with alternative building materials, the glass elements are much more lightweight, rendering the glass structure considerably smaller. This is particularly helpful in facilities that are facing space limitations as well as in work environments where headroom’s can become a problem. The lightweight structure can also make packaging, distribution and installation simpler.

Affordability of Commodities

Glass is comparatively inexpensive to manufacture compared to other building materials that give comparable properties, such as corrosion resistance. Glass is an incredibly economical alternative relative to other solutions such as quartz. Its sustainability is an additional aspect that contributes to its affordability; with careful repair and care, the glass equipment may have a long-life cycle.

Applications of Borosilicate Glass

When borosilicate glass became available, it was quickly evident in its applications. For borosilicate glass, some

of the common uses include:

- Lab glassware

- Glass Pilot Plant & kilo Lab

- Scientific lenses

- Bakeware and cookware

- Thermal insulation

- high-intensity lighting /well glass

- Sight glass

- Aircraft exterior lenses

- Aquarium heaters

- Electronics

- Scientific Glassware

Looking for Best Manufacturer of Glass Pilot Plants & Turnkey Projects?