Sulfuric Acid Dilution Plant

Sulfuric acid can be used directly or indirectly in the manufacturing process of dyes, fertilizers, intermediates, and many more. Sulfuric acid used for commercial purposes is readily available, with around 98% concentration levels. Several processes where the application of Sulfuric acid is necessary; it needs you to dilute the highly concentrated sulfuric acid to medium or low levels that are to be used in the reactions. The process of Dilution of Sulfuric Acid is said to emit a significant amount of heat that poses many engineering challenges.

Just like any other acid, Sulfuric acid is extremely toxic as well as corrosive and has proven results of reacting aggressively with the metals, concerning their operating parameters and strength. Hence, there are very few materials of Construction who are compatible and capable of handling, processing, and storing the Sulfuric acid. Therefore, unique design and particular knowledge are needed for the smooth operation of the Sulfuric Acid Dilution Plant that can handle Sulfuric acid with utmost care.

Ablaze holds a successful record of designing and supplying various Engineered systems for the mineral acids. Apart from manufacturing the Borosilicate Glass equipment, PTFE components, as well as PTFE, lined components, Ablaze is highly qualified and capable of handling such systems as these materials of Construction are majorly used in such systems. Ablaze also employs the domestic capabilities for the process of Automation and Instrumentation that is highly recommended for reliable and safe operation.

Custom made designs are offered for Sulfuric acid dilution systems, depending on the initial and final concentrations of acid, cooling medium available, etc.

Sulphuric acid withholds an ample of applications that are useful in a variety of chemical reactions. Commonly available sulphuric acid is usually diluted with water as well as contaminated with trace chemicals. Since most chemical reactions use concentrated sulphuric acid, the process of recovery of concentrated acid is essential.

Over the last 30 years, Ablaze has acquired sufficient process know-how for the process. We offer complete turnkey units for a concentration of sulphuric acid. Based on initial feed concentration, we do process design and engineering to give output acid of the desired concentration.

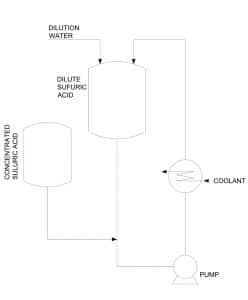

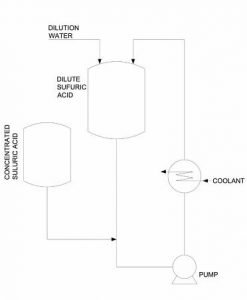

Two methods used in Sulfuric Acid Dilution Plant

- Re-circulatory or Batch process – This method is usually used in the industries who have small or medium capacity units.

- Once through a process or Continuous process – This method is usually used in the industries that have medium or high capacity units.

Advantages of Sulfuric Acid Dilution

- The Sulfuric Acid Dilution System can produce the diluted sulfuric acid continuously to an entitled level of concentration via diluting the concentrated sulfuric acid with the help of a dispersion mixer.

- It is considered safe to work with because it is designed inline.

- Heat exchanger removes the excess heat produced during the dilution process, and you can cool the diluted sulfuric acid by adjusting temperature rapidly.

- The system helps in maintaining the pressurized pipes and also has a back pressure valve, which eliminates the vapors of the diluted sulfuric acid.

- The system design is highly compact and only takes up a little space for installation.

- Working in the system is fully automatic, which makes it easy to operate.

Utilities Required for the Sulfuric Acid Dilution

The list of the required utilities are as follows

- Steam or Thermic fluid,

- Cooling water and Power supply (may vary concerning the feed rate),

- Feed Concentration,

- Product Concentration.

For instance, if a plant has 50TPD feed which contains 50% H2S04 (Sulfuric Acid) the usage of utilities to achieve a minimum of 70% concentration are as below;

-

- Steam at 6 bar (g) pressure : 800 Kg/hr

- Cooling Water at 30°C : 70 Cu M/hr

- Power : 15 KW

Process

It is a straightforward process to follow, which involves the adequate concentration of diluted sulfuric acid done via an evaporation method using the steam under vacuum. The diluted solution is then preheated and provided to a range of evaporators in various stages to achieve the desired concentration level. The vapors rising from the evaporators are then compressed and drained out via barometric legs, and also you can remove the non-condensables with the help of an ejector. The final product is then cooled and stored in the storage tank.

The System Consists the following

- Dilution Chamber

- Glass Heat Exchanger

- Glass Buffer (receiver) for the Circulation of diluted sulfuric acid

- Circulation pump for Diluted Sulfuric Acid

- Valves, Glass Pipelines, and Thermowell.

Explore Our Products

Looking for Best Manufacturer of Glass Pilot Plants & Turnkey Projects?