Product Description

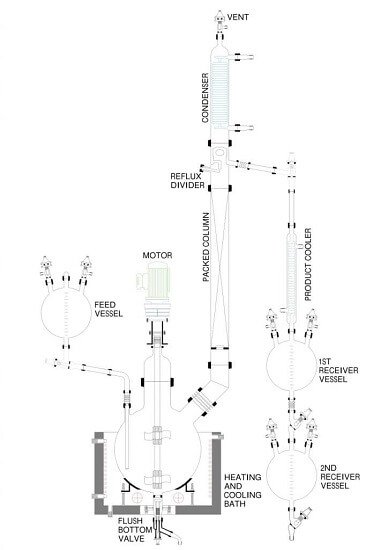

Reflux Reaction Distillation Unit is a flexible unit that can be used either as a Reaction Distillation Unit, Fractional Distillation Unit or as a combination of both. It incorporates all characteristics of the Reaction Distillation Unit and Fractional Distillation Unit.

Reflux Reaction Distillation Unit Glass Reactor Pilot Plant Manufacturer & Supplier. Units are available in 50, 100, and 200 liters up to 500 liters in vessel sizes. Suitable for atmospheric pressure and full vacuum operations.

This system can be used as a breakdown or distillation or as a mixture of both reactions. The Reflux Reaction Cum Distillation System is available with high capacity, reliable efficiency, long service life, high reliability, and competitive market prices.

We are committed to providing our customers with a broad range of reflux reaction and distillation systems. The provided distillation unit is commonly used for the study and processing of the distillation material in various laboratories.

The term reflux has been used in many industries using columns and fractionators for large-scale distillation, such as oil refineries, petrochemical, chemical, and gas plants.

In this sense, reflux refers to a part, as shown in the scheme of a typical industrial distillation column, that of the overhead fluid component of a distillation column or fractionator which is returned to the upper portion of the column. The downflowing reflux fluid in the column provides the up flowing vapors with cooling and condensation, thus increasing the distillate column efficiency.

Salient Features

- Reactor up to 500-liter capacity

- ” ZERO” Hold Up with Temperature Sensing Valve

- Quick Closer for the addition of Solid

- Visual monitoring of the process, improving safety and reliability of production

- Dual functional heating & cooling oil/water bath

- Can be designed for the batch as well as continuous operations

- All wetted parts are made from Borosilicate Glass, and PTFE, providing universal corrosion resistance

- Low CAPEX, and easy to maintain

- Suitable for installation in fume hoods

- Zero Hold-up in reflux

- Wide range of operation -90°C to +250°C available on request

Dimension Table

| DESCRIPTION | ARRDU 50 | ARRDU 100 | ARRDU 200 | ARRDU 500 | |

|---|---|---|---|---|---|

| Reactor Nominal Capacity | ltr. | 50 | 100 | 200 | 500 |

| Heat Exchanger (Exchange Surface) | m2 | 0.5 | 1.5 | 2.5 | 5 |

| Bath Heather Capacity | kW | 6 | 8 | 12 | 18 |

| Vessel Design Pressure | bar(g) | -1 to +6 | -1 to +0.5 | -1 to +0.4 | -1 to +0.3 |

| Plant Working Temperature | ºC | -20 to +180 | -20 to +180 | -20 to +180 | -20 to +180 |

| Plant Design Temperature | ºC | -25 to +200 | -25 to +200 | -25 to +200 | -25 to +200 |

| Plant Working Pressure | bar(g) | +0.5 | +0.4 | +0.3 | +0.2 |

| Feed Vessel | No. × ltr. | 1 × 5 | 1 × 10 | 1 × 20 | 1 × 50 |

| Receiver Vessel | No. × ltr. | 2 × 5 | 2 × 10 | 2 × 20 | 2 × 50 |

| Vapour Line Column | DN | 50 | 100 | 150 | 200 |

| Rupture Disc | bar(g) | 0.5 | 0.5 | 0.5 | 0.5 |

| Stirrer Speed | rpm | 20 to 250 | 20 to 250 | 20 to 250 | 20 to 250 |

Looking for Best Manufacturer of Glass Pilot Plants & Turnkey Projects?