Product Description

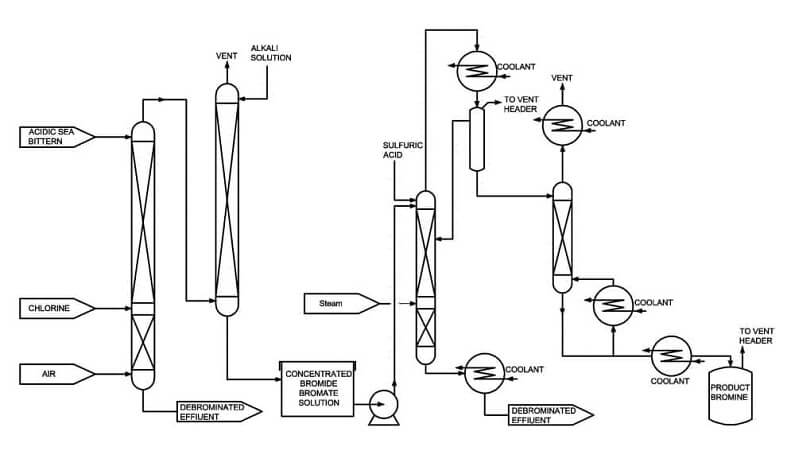

The acidified feed containing Bromide salts is fed to Reactioncum- Air blowing tower, where dry Chlorine gas and Low-Pressure Air are injected. The Chlorine gas liberates free Bromine which is stripped out by Air in form of vapors. These vapors enter Absorption tower where Alkali solution is circulated and a Bromide-Bromate solution is formed. The Bromine content in the resultant solution is highly enriched compared to the original content. The unabsorbed air is vented out.

The enriched Bromide-Bromate solution is subjected to acidification in the liberation tower, where Bromine vapors are liberated and stripped out by steam injected at the bottom of the tower. The vapors leave the top of the tower.

These vapors are condensed in a series of condensers, and condensate is collected in the phase separator. The water phase is separated from Bromine and is refluxed to the tower. The Bromine so separated is Crude Bromine and is subjected to distillation.

Under distillation, Chlorine is removed and pure Bromine collected as bottom product. This Bromine is cooled through Product coolers and collected in product receiver/s. A Vent condenser condenses most of the Bromine and recycles into the system. The non-condensable are taken to the Vent scrubber.

The dibrominated effluent from the Air blowing tower may be taken for neutralization and effluent treatment.

Quick Inquiry

Looking for Best Manufacturer of Glass Pilot Plants & Turnkey Projects?