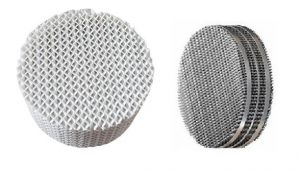

Structured Packing

We are Ablaze Export Pvt. Ltd., one of the best Structured Packing manufacturers and Exporters in the business. They strive to provide you with only the best quality products having high durability and efficiency.

Regardless of this scenario, the structured packing materials are used to improve the vapor-liquid connection. Hence, it has plenty of areas that need improvements that are promptly available for promoting fluid growth over the packaging surface. Our complete range of products is manufactured using the top quality raw materials.

We are truly determined to provide our clients with excellent quality products. Our competent professionals use stainless steel to manufacture the products. This mixture is basically made up of the alloy of nickel, chromium, carbon, nitrogen, and many other elements. These elements show various properties when combined together. The alloy possesses considerable tensile strength as well as high resistance qualities against corrosion and is known to withstand high temperatures. We ensure using this material in our products helps in packing our products with eminent features such as reliability and durability.

Our structured packings are highly effective, as well as economical. These packings are exceptionally in demand for the process of azeotropic liquid separation. They tend to be more efficient as compared to the other common types of packings. They help in sustaining the high capacity and better characteristics in the resultant product. Traditional packing has certain limitations such as layer interface and much more. Our structured packings are known to provide you with the best solution for your applications. We also ensure the proper arrangement of the structured packings based on sheets.

The Structured Packings based on the Wire-Web design are another type of packing that we offer to our clients. We have comprehensively rich experience on the basis of which we can assure you an appropriate transfer of mass. We are putting a continuous effort in improving our designs that can match the best quality standards of the market and provide the most effective and the best-in-class structured packings to our clients.

Pertinent Features of Structured Packing

- It has a considerable void volume in the packing materials.

- It has a significant surface area for mass transfer.

- It works absolutely fine at super low-pressure levels and is highly favored to use for the vacuum distillation process.

- It has a significant vapor load capacity as compared to the random packing materials.

- It can handle the pressure drop up to 0.5-1.5 mbar/m per theoretical stage considering the Standard System.

Specifications

- They are offered with certain specifications of the surface areas having the mass transfer of various sizes and capacity.

- Materials that are used, such as Stainless Steel 304/304L, SS 316/ 316L, etc.

Applications of Structured Packing

- It can be used in a wide range of industries, from laboratories to extensive scale processes.

- It can be used for solvent revival.

- It can be used for closure of the boiling components distillation.

- It can be used for Azeotropic distillation.

- It can be used in high vacuum processing columns.

- It is highly suitable for the batch as well as the continuous distillation processes.

Final Thoughts

Ablaze Export Pvt. Ltd. is a leading manufacturer of high-performing Structured Packing that can fit your application’s demand. We are Vadodara based structured packing suppliers. All our structured packing materials attribute a series of uniquely designed materials that are used in the absorption process, distillation columns, as well as the chemical reactors. Its unmatched quality and the exclusive design has boosted their performance as well as their capacity.

Looking for Best Manufacturer of Glass Pilot Plants & Turnkey Projects?