Product Description

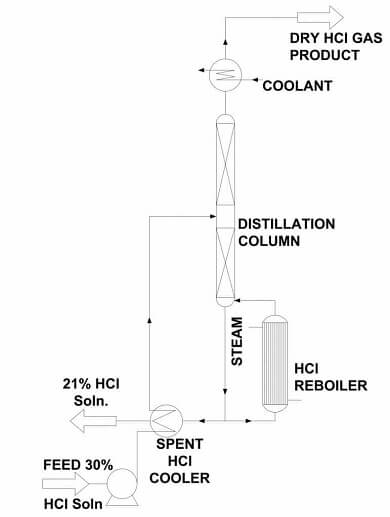

The plant produces dry HCl gas by the process of distillation of 30% hydrochloric acid solution as a continuous process. The feed 30% HCl acid is preheated by the outgoing hot bottom product in the heat exchanger and fed to the azeotropic distillation column by the pump in a controlled rate. The heat energy is supplied by steam to the thermosiphon reboiler at bottom of the column.

The bottom product from the plant is constant boiling approx 21% acid solution which is cooled by the cold 30% acid feed solution prior to discharge.

The top product HCl gas is dried in the Drying Unit using Sulfuric acid / suitable dehydrating agent. The product HCl gas is anhydrous.

All the wetted parts of the system are fabricated from corrosion resistant materials (Glass and Graphite).

Salient Features

- Medium capital cost

- Simple process

- Compact design

- Pure 21% HCl as bottom product

- Low operating cost

Looking for Best Manufacturer of Glass Pilot Plants & Turnkey Projects?