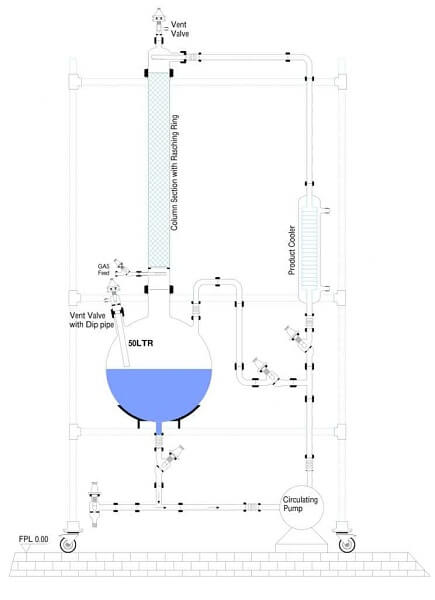

Product Description

Ablaze Export Pvt. Ltd. manufactures the best-in-class Gas scrubbers that are commonly used as a tool to smoothen the toxic and corrosive exhaust gases, before releasing it. The stripping liquid is preferred concerning the nature of the vapor that needs to be scrubbed. A recirculation pump used as the corrosion-resistant is taken into consideration, which assures a continuous flow of the solvent through the system. The gas and the solvent will get mixed in the column, which is sealed to observe a sharp increase in the surface area needed for the smooth absorption of gas. Dry scrubber system is available in a wide range of scales from lab scale to the pilot scale in the variants of 500L.

Technical Data

- It has a capacity of 5 liters to 500 liters in a spherical vessel

- The exhaust gas temperature ranges from -60 to +150°C

- The scrubbing liquid temperature ranges from 0 to 80°C

- The operating pressure ranges between -1.0 to +0.5 bar G

- The material of Construction consists of the borosilicate Glass 3.3, PTFE. We also offer customized configurations and will design the equipment as per your requirements.

- The circulation pump consists of PTFE/PVDF that are lined up in the Centrifugal Pump.

Applications

- In the neutralization of exhaust gases

- In the scale-up Studies

- In the gas-Liquid Reaction

- Gas Absorption

Pertinent Features for Gas Scrubbers

- It has significant corrosion-resistant properties.

- It is portable and highly compact in design.

- The optimal circulation temperature is adequately maintained.

- It is capable of handling considerable gas flow rates.

- It is flameproof and has PVDF Pump and ATEX.

- The spiral product cooler helps in retaining the solvent temperatures.

- It comes with complete documentation and certificates (IQ /OQ / DQ).

- It can be easily integrated with the Reaction Systems.

- Its transparency helps in a better understanding of the running process.

- The pH scale of the scrubbing liquid can easily be monitored.

Design Considerations

Below-mentioned is some of the crucial design considerations for the Gas Scrubber

- Pollutant Targeted

- Removal Efficiency

- Process Conditions

The efficiency of the Gas Scrubber removal process can be achieved via ensuring the suitable time of contact between the scrubbing liquid and the gas. These units include a scrubbing vessel that comes with a system fan, a recycling pump, controls as well as instrumentation, and the exhaust stack. The packed bed Gas Scrubbers consists of a random packing that facilitates the contact between gas and liquid. The exhaust gas will enter the scrubber, where it will come into contact with the scrubbing fluid, and the fluid will capture all the pollutants and will collect it for discharging or treating it for the reusing purposes.

Options Available

- It is available with 14C rated API.

- It is available with high and low-level controls.

- It is available with flanged connections.

- It is available with the skid-mounted having a drain pan.

- It is available with cleanouts and manways.

- It is available with concrete blocks.

- It is available with carbide trim.

- It is available with a sour gas service that is designed and built according to the NACE standards.

- It is available with all the customization you require that meets all the additional specifications.

Benefits

- The accelerated production drawings are readily available within 4-5 business days that will help you in planning things faster and in a better way.

- It comes with a single well as well as multi-well designs that are available with the full pad well designs.

- It has a robust skid design and is committed to serve and help in bringing results to the online operations quickly.

- It is significantly cost-effective and low in maintenance.

- The commissioning and installation of the system is an easy process to follow that will help in facilitating and speeding the startup.

Looking for Best Manufacturer of Glass Pilot Plants & Turnkey Projects?