Product Description

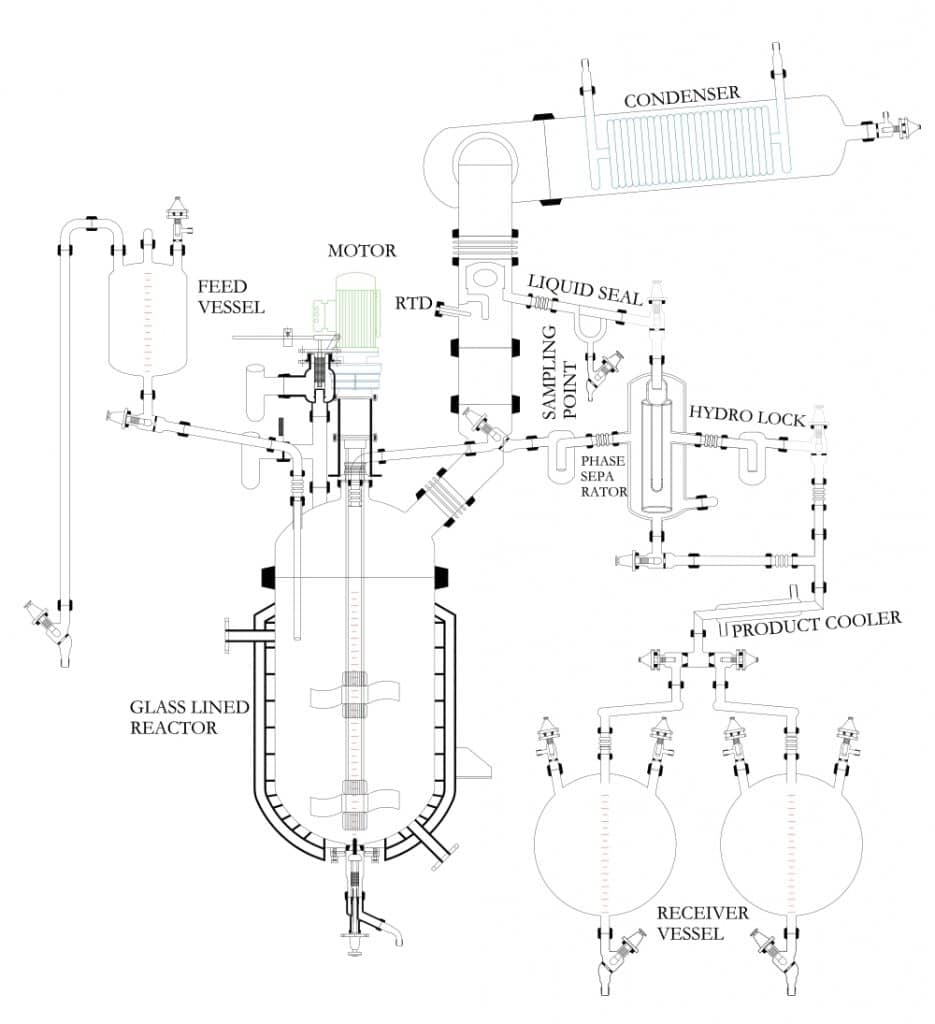

Ablaze Export Pvt. Ltd. intends to offer the definitive distillation systems with the Glass Lined Reactor along with the other assembly items as same as type AGR. This will undoubtedly help to upscale it up to the production design, and it helps in replicating the conditions of the production process much more closely.

The construction material is indeed a prime aspect in the equipment selection process, exclusively when you are dealing with a product that demands a higher level of corrosion resistance property and purity too. In this case, the glass, as well as glass linings, are the most likely choices among the top ones. Both of them offer similar benefits; however, some distinct differences highlight their characteristics separately.

Pertinent Features of Glass Lined Reactor With Glass Cover

- It is highly suitable to have a significant value, a low volume production level making it work from around 25 liters to 630 liters.

- It has clear visibility or transparency that would work better to have a fair understanding during the development of the whole process.

- The Glass Lined Reactor is capable of working for cryogenic reactions under the temperature around -90°C.

- It has a Glass Lined Steel Stirrer that helps to achieve zero contamination.

- It has excellent mechanical stability and supports the heat transfer.

- It is CIP Capable.

- It is equipped with twin distillate receivers to keep the operation continuing without breaking a vacuum.

- It baffles with the PT100 when the temperature sensors are provided.

Advantages of Glass Lined Reactor With Glass Cover

The mixture of metal-glass material in the production administers the advantages of both of the prime peripherals. Extraneous steel production will offer much-needed strength to the Glass Lined Reactor. At the same time, the lining on the internal glass will surely give them protection against global corrosion and also have a non-contaminating smooth surface. It will result in the following:

- A corrosion-resistant property against both the acids as well as the bases.

- Immense operating pressure and temperature.

- The ability of adding and removing the heat to the batch.

Dimension Table

| DESCRIPTION | UNIT | AGR/GL 25 | AGR/GL 50 | AGR/GL 100 | AGR/GL 250 |

|---|---|---|---|---|---|

| Reactor Nominal Capacity | ltr. | 25 | 50 | 100 | 250 |

| Heat Exchanger (Exchange Surface) | m2 | 0.5 | 1.0 | 1.5 | 3.0 |

| Jacket Design Pressure | bar(g) | -1 to +6 | -1 to +6 | -1 to +6 | -1 to +6 |

| Vessel Design Pressure | bar(g) | -1 to +6 | -1 to +6 | -1 to +6 | -1 to +6 |

| Plant Working Temperature | ºC | -20 to +180 | -20 to +180 | -20 to +180 | -20 to +180 |

| Plant Design Temperature | ºC | -25 to +200 | -25 to +200 | -25 to +200 | -25 to +200 |

| Plant Working Pressure | bar(g) | +1.0 | +0.7 | +0.5 | +0.5 |

| Feed Vessel | No. × ltr. | 2 × 5 | 1 × 10 | 1 × 20 | 1 × 50 |

| Receiver Vessel | No. × ltr. | 2 × 5 | 1 × 10 | 1 × 20 | 1 × 50 |

| Vapour Line Column | DN | 50 | 80 | 100 | 150 |

| Rupture Disc | bar(g) | 0.5 | 0.5 | 0.5 | 0.5 |

| Stirrer Speed | rpm | 20 to 250 | 20 to 250 | 20 to 250 | 20 to 250 |

Looking for Best Manufacturer of Glass Pilot Plants & Turnkey Projects?